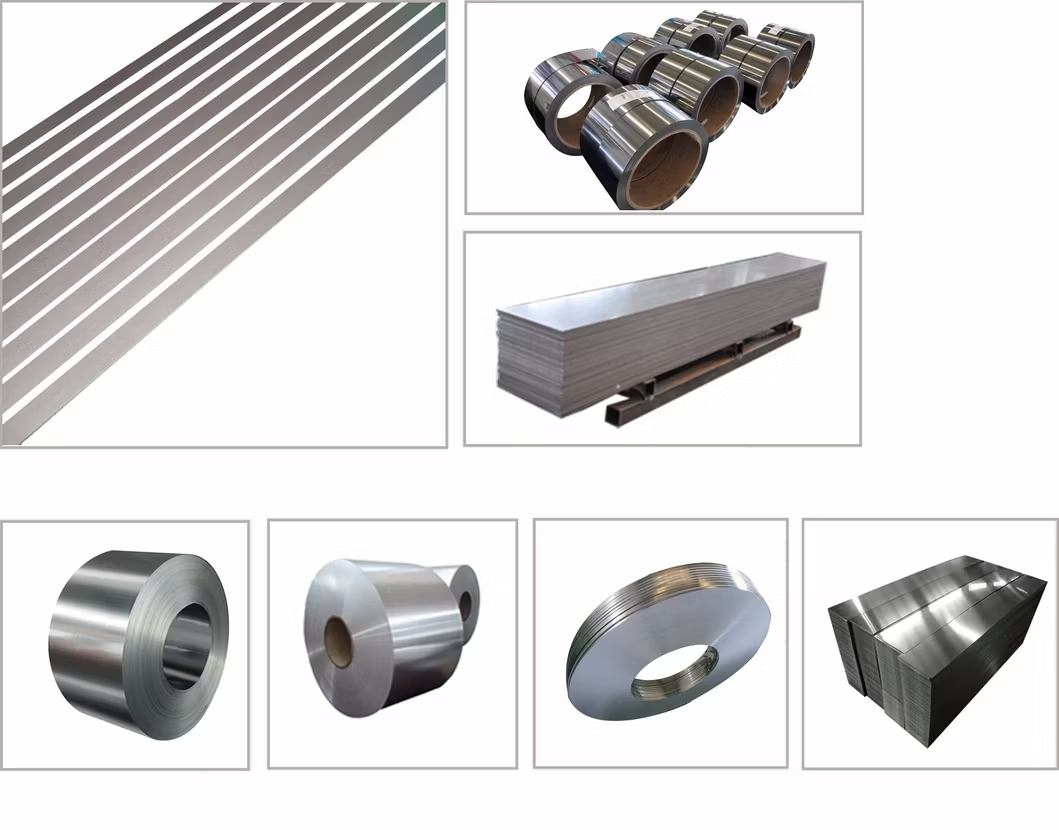

Product Introduction

| Standard | C≤% | Mn≤% | P≤% | S≤% | Si≤% | Cr | Ni≤% |

| ASTM A240 | 0.12 | 1.00 | 0.040 | 0.030 | 1.00 | 16.0-18.0 | 0.75 |

| JIS G 4305 | 0.12 | 1.00 | 0.040 | 0.030 | 0.75 | 16.0-18.0 | |

| GB/T4237-2015 | 0.12 | 1.00 | 0.040 | 0.030 | 1.00 | 16.0-18.0 | |

| Standard | T.S. min | Y.S. min | EL min% | HARDNESS( max) | BEND | ||

| Mpa | Mpa | 50mm | HBW | HRB | HV | ||

| ASTM A240 | 450 | 205 | 22 | 183 | 89 | 180 | |

| JIS G 4305 | 420 | 205 | 22 | 183 | 88 | 200 | 180 |

| GB/T4237-2015 | 420 | 205 | 22 | 183 | 89 | 200 | 180 |

| Precision stainless steel strip | Re-rolling stainless steel coil & sheet | ||||||

| Thickness | 0.08-1.2mm | Thickness | 0.4-4.0mm | ||||

| Rolling width | 450-680mm | Rolling Width | 550-680mm | ||||

| Slitting width | 5-680mm(We can slitting for you as per you required width,but if you need some special width such as 400mm coil the remaining 280mm you also need to purchase which can not sale to other clients) | Slitting width | 25-680mm(We can slitting for you as per your required width,but if you need some special width such as 400mm coil the remaining 280mm you also need to purchase which can not sale to other clients) | ||||

| Length | coil or as per requirement. | Length | as per requirement | ||||

| Surface | 2B | Surface | 2B | ||||

| Original | DSM | Standard | Produce as per your requirement. | ||||

| Standard | Produce as per your requirement. | MOQ for coil | 5mt or as per coil actual weight | ||||

| MOQ | 3mt or as per coil actual weight | MOQ for sheet | 5 Pcs | ||||

| Hot rolled stainless steel coil sheet | Cold rolled stainless steel coil & sheet | ||||||

| Thickness | 3.0-12.0mm | Thickness | 0.3-3.0 mm | ||||

| Width | 1219mm | Width | 1000,1219,1500 | ||||

| Length | coil or as per requirement. | Length | coil or as per requirement. | ||||

| Surface | No.1 or 1D | Surface | 2B | ||||

| Original | TISCO | Original | TISCO | ||||

| Standard | GB/T4237-2015 ASTM A240/A240M JIS G4304 | Standard | GB/T3280-2007 ASTM A240/A240M JIS G4305 EN10088-2:2005 | ||||

| MOQ for coil | 13mt or as per coil actual weight | MOQ for coil | 5mt or as per coil actual weight | ||||

| MOQ for sheet | 5 Pcs | MOQ for sheet | 5 Pcs | ||||

Application

These alloys are used in a variety of interior and exterior trim applications where corrosion resistance is more

important than high strength. Typical applications are sinks and sink rims, appliance trim and counter tops.

Type434 is used mainly for automotive trim and other more severe exterior environments.

For supplementary information on product forms, applications, conditions, sizes, finishes, coatings and pattern

finishes see the Allegheny Ludlum Stainless Steel Brochure Series SS91.98. Information on specifications is

contained in pamphlet SS90.

GENERAL PROPERTIES

Allegheny Stainless Types 430 and 434 are low carbon ferritic stainless steels which, in mildly corrosive

environments or atmospheric exposures, have corrosion resistance approaching that of some nickel

stainless steels. These alloys are oxidation resistant at elevated temperatures. Types 430 and 434 are

ductile, do not work harden readily, and can be formed using a variety of roll forming or mild stretch

bending operations as well as the more common drawing and bending processes.

These alloys are used in a variety of interior and exterior trim applications where corrosion resistance is more

important than high strength. Typical applications are sinks and sink rims, appliance trim and counter tops.

Type434 is used mainly for automotive trim and other more severe exterior environments.

For supplementary information on product forms, applications, conditions, sizes, finishes, coatings and pattern

finishes see the Allegheny Ludlum Stainless Steel Brochure Series SS91.98. Information on specifications is

contained in pamphlet SS90.

GENERAL PROPERTIES

Allegheny Stainless Types 430 and 434 are low carbon ferritic stainless steels which, in mildly corrosive

environments or atmospheric exposures, have corrosion resistance approaching that of some nickel

stainless steels. These alloys are oxidation resistant at elevated temperatures. Types 430 and 434 are

ductile, do not work harden readily, and can be formed using a variety of roll forming or mild stretch

bending operations as well as the more common drawing and bending processes.

Factory

Production process

Certificate

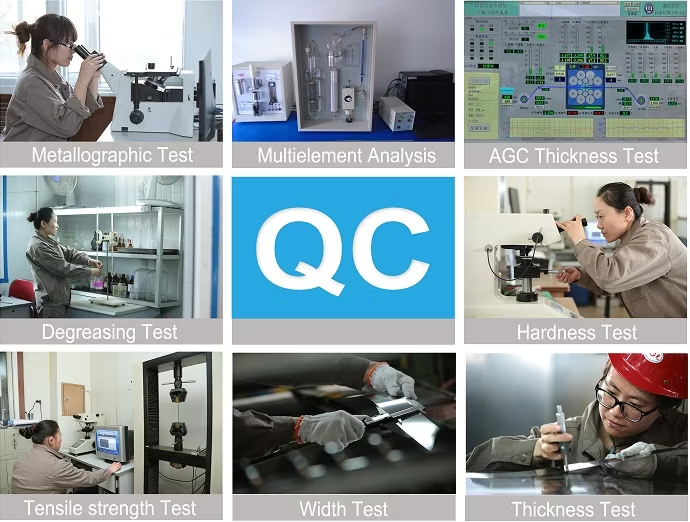

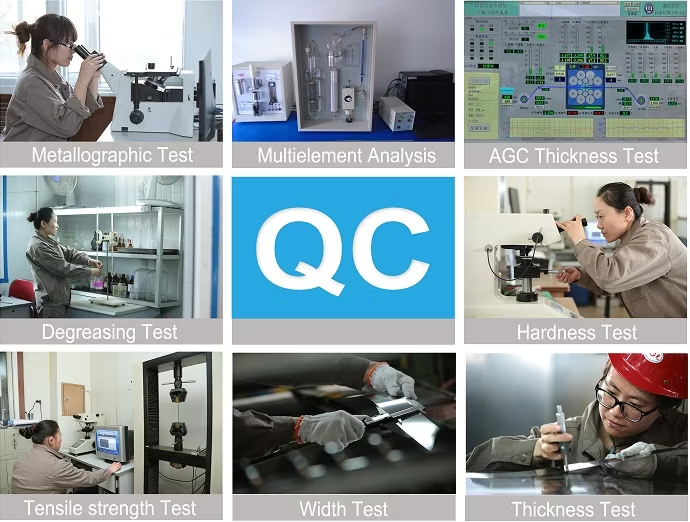

Quality control

Contact

Production process

Certificate

Quality control

Contact